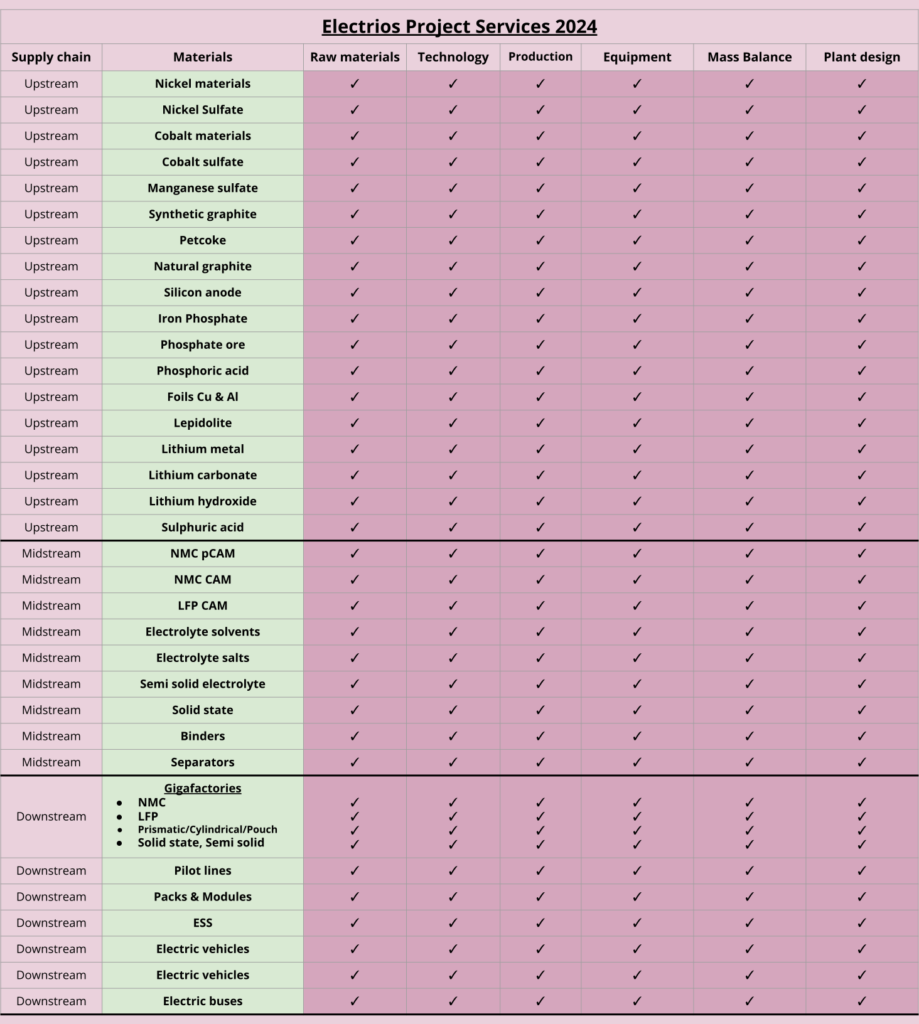

Electrios: Complete EV battery Industry Solutions

Building an EV battery industry requires a comprehensive range of services, encompassing the entire value chain from raw material extraction to battery recycling. Electrios is a leading provider of end-to-end EV battery solutions, offering everything from raw material extraction to battery recycling. Electrios’s comprehensive approach ensures that customers have the support they need to navigate the complex EV battery industry landscape.

1. Raw Material Processing

- Raw Materials: Lithium, cobalt, nickel, and manganese.

- Operations: Processing these minerals to obtain the required purity and form for battery production.

- Refining: Refining the extracted minerals into high-quality materials suitable for battery cathodes, anodes, and electrolytes.

2. Battery Manufacturing

- Cathode Manufacturing: Mixing and coating active materials, binders, and conductive additives to form cathodes.

- Anode Manufacturing: Processing graphite and other conductive materials to prepare anodes.

- Electrolyte Manufacturing: Combining chemicals like lithium salts, solvents, and additives to form electrolytes.

- Cell Assembly: Combining cathodes, anodes, electrolytes, and separators to assemble individual battery cells.

- Module and Pack Assembly: Grouping individual cells into modules and assembling modules into battery packs.

3. Equipment

A wide range of specialized equipment is required for each step of the EV battery production process:

- Mixers: For mixing active materials and additives for cathodes and anodes.

- Coating Machines: For coating the active materials onto conductive substrates.

- Mills: For grinding and pulverizing materials into fine particles.

- Electroplating Systems: For depositing metal layers onto electrodes.

- Sealing Machines: For sealing battery cells and modules.

- Automatic Assembly Systems: For automating the assembly of cells and modules into packs.

4. Plant Design

The layout and design of EV battery manufacturing plants are crucial for efficiency, safety, and environmental sustainability:

- Material Handling Systems: Efficiently transporting raw materials, components, and finished products within the plant.

- Control Systems: Monitoring and automating processes to maintain quality and optimize production.

- Safety Features: Implementing safety measures to prevent accidents and protect workers.

- Environmental Controls: Minimizing environmental impact through waste management, energy efficiency, and water conservation measures.

5. Quality Control and Testing

- Raw Material Analysis: Testing the quality and purity of raw materials to ensure adherence to specifications.

- Process Control: Continuous monitoring of manufacturing processes to detect and prevent defects.

- Cell Testing: Conducting rigorous testing of individual battery cells to evaluate their performance and safety.

- Module and Pack Testing: Performing comprehensive testing of battery modules and packs to ensure they meet safety and performance standards.