𝐂𝐨𝐚𝐭𝐢𝐧𝐠-𝐋𝐢𝐭𝐡𝐢𝐮𝐦-𝐢𝐨

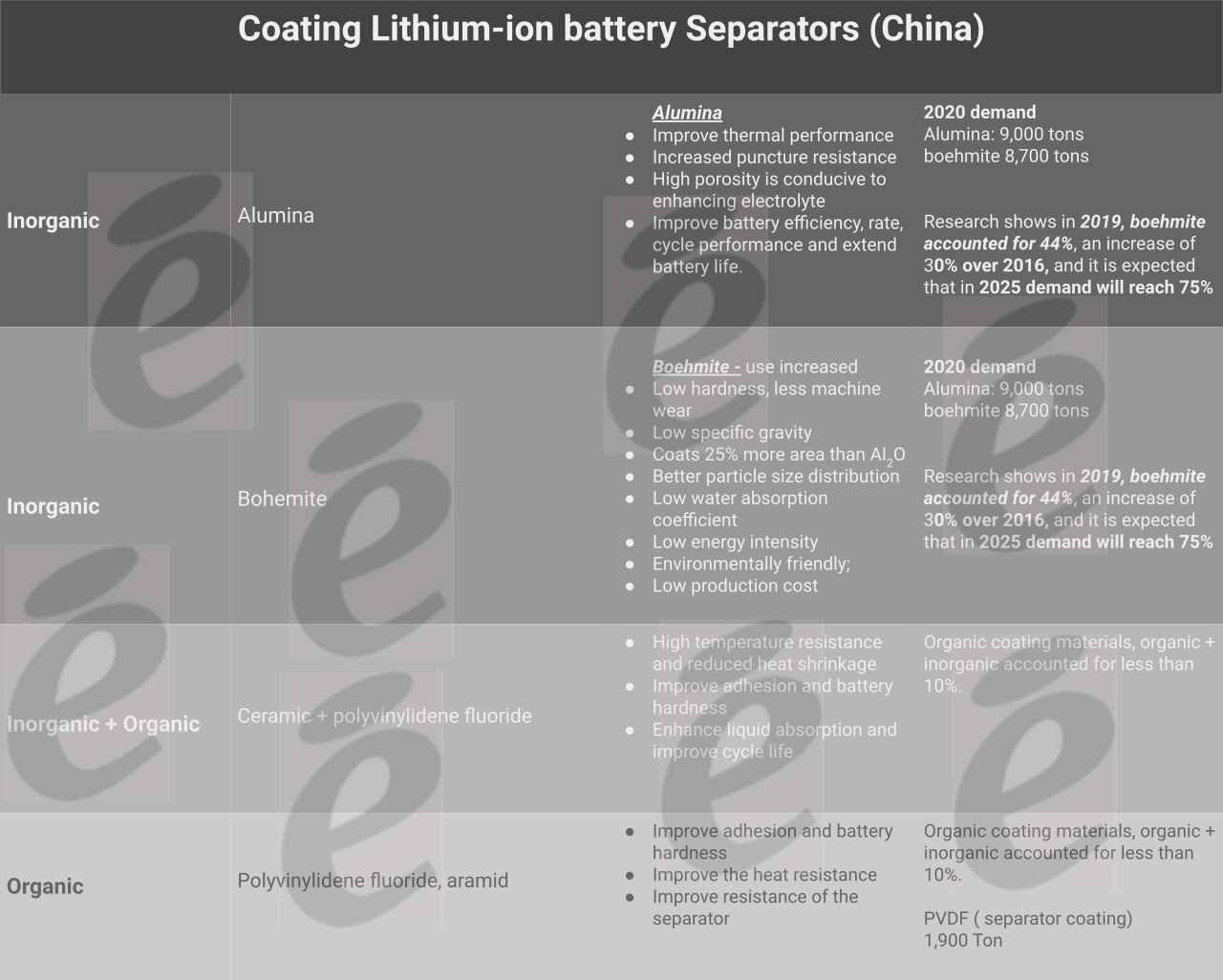

We put the table below together to shed a little light on coating materials used on Chinese lithium battery separators and where the market is heading.

Alumina

- Improve thermal performance

- Increased puncture resistance

- High porosity is conducive to enhancing electrolyte

- Improve battery efficiency, rate, cycle performance and extend battery life

- High Purity Alumina (HPA)

Boehmite – use increased

- Low hardness, less machine wear

- Low specific gravity

- Coats 25% more area than Al2O3

- Better particle size distribution

- Low water absorption coefficient

- Low energy intensity

- Environmentally friendly;

- Low production cost

2020 demand

Alumina: 9,000 tons

Boehmite 8,700 tons

Research shows in 2019, boehmite accounted for 44%, an increase of 30% over 2016, and it is expected that in 2025 demand will reach 75%