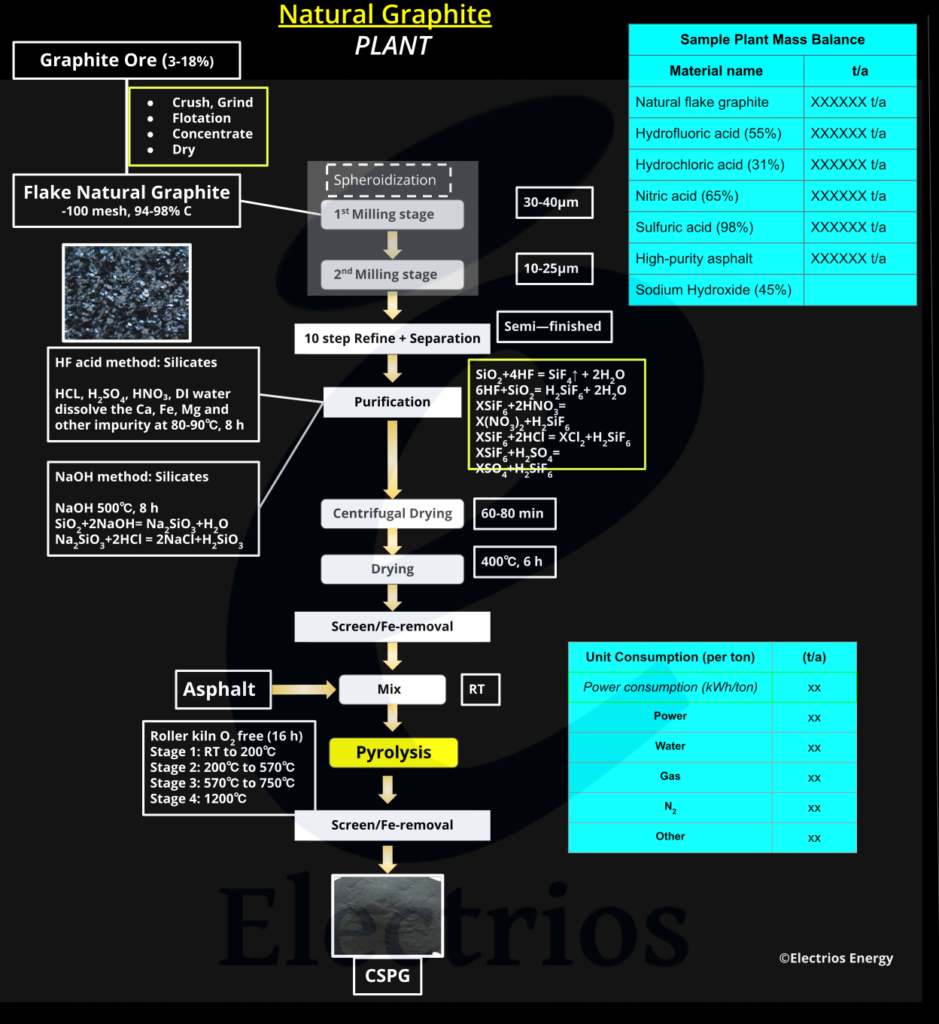

Battery Natural Graphite Refining

Natural graphite is a crucial component in lithium-ion batteries (LIBs), serving as the anode material responsible for storing and releasing lithium ions. The production of natural graphite anodes for LIBs involves a series of steps, from mining and processing to refining and spheroidization.

Mining and Processing:

The first step in natural graphite anode production is mining graphite ore from natural deposits. The ore is then crushed and milled into a fine powder, known as graphite concentrate. This concentrate is further purified through processes like flotation, frothing, and electrostatic separation to remove impurities like clay, quartz, and other minerals.

Refining:

The purified graphite concentrate is then refined to improve its physical properties, such as particle size distribution, crystallinity, and surface area. This typically involves high-temperature treatment, such as heat treatment or carbonization, to remove residual impurities and enhance the structure of the graphite.

Spheroidization:

Spheroidization is a crucial process that transforms flake graphite particles into spherical particles. This is done to improve the electrochemical performance of the graphite anode by increasing its surface area, charge-storage capacity, and cycle life.

Purification Methods:

Chemical Leaching: This method utilizes acids or alkaline solutions to dissolve the impurities from the graphite particles. Hydrofluoric acid (HF), hydrochloric acid (HCl), and sulfuric acid (H2SO4) are commonly used for this purpose

Formulation and Coating:

The final stage involves formulating the spheroidized graphite with additives, such as binders, conductive agents, and dispersants, to create a homogeneous mixture. This mixture is then coated onto a conductive substrate, such as copper foil, to create the fully functional graphite anode for LIBs.

The production of natural graphite anodes for LIBs is a complex and energy-intensive process. Electrios strategies to optimize the production process, reduce energy consumption, and minimize environmental impact.