Cell Inversion Revolutionizing EV Batteries

The relentless pursuit of greater efficiency and safety in electric vehicles has spurred continuous innovation in battery technology. One of the most intriguing developments in recent years is cell inversion, a design concept that challenges traditional battery pack architecture.

What is Cell Inversion?

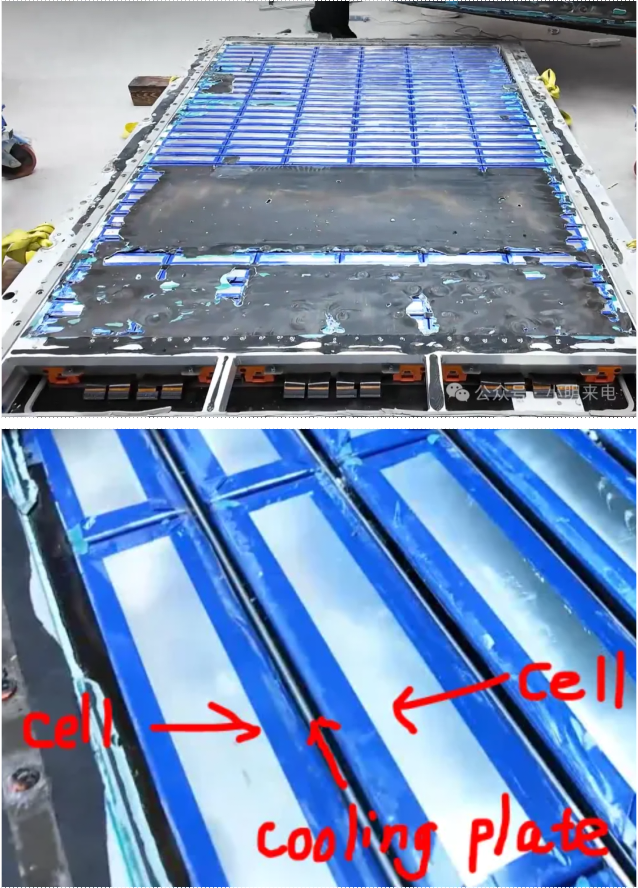

In a conventional EV battery pack, prismatic cells are neatly arranged in an upright position. Cell inversion, as the term implies, flips this arrangement, placing the cells upside down. This seemingly simple modification carries significant implications for both space utilization and safety.

Space Efficiency: Making Every Millimeter Count

One of the key drivers behind cell inversion is the desire to maximize space within the battery pack. In a traditional upright configuration, the area above the battery cell terminals is occupied by components like the busbar, insulation sheet, and cables. Inverting the cells allows OEM to reclaim this otherwise wasted space and merge it with the mandatory safety buffer zone at the bottom of the pack. This clever innovation yields an additional 5-10mm of vertical space, translating to a notable 6% increase in overall space utilization.

Safety Enhancement: Prioritizing Passenger Protection

Beyond space efficiency, cell inversion offers a crucial safety advantage. In the event of a thermal runaway – a dangerous scenario where a battery cell undergoes uncontrolled overheating – the downward-facing pressure relief valve inherent in the inverted design enables rapid downward venting of heat and pressure. This directional venting effectively minimizes the risk of heat and pressure propagating upwards into the passenger compartment.

The Xiaomi SU7

The Xiaomi SU7, launched in December 2023, holds the distinction of being the world’s first mass-produced vehicle to incorporate cell inversion technology using CATL Kirin battery, which features cell inversion.

However, the implementation of cell inversion in the SU7 came with unique challenges that demanded ingenious solutions.

- Electrolyte Immersion: The inverted orientation of the cells resulted in the submersion of both the terminals and the pressure relief valve in electrolyte. This presented a potential risk of increased electrolyte working temperature and reduced battery lifespan. To combat this, Xiaomi and CATL jointly developed a custom-designed macromolecular high-temperature resistant electrolyte with an operating temperature 10-15°C higher than standard electrolytes. This special electrolyte effectively addressed the immersion issue and extended the battery cell lifespan to over 15 years.

- Corrosion of Pressure Relief Valve: The inverted position also accelerated the corrosion rate of the pressure relief valve. To ensure longevity, aviation-grade corrosion-resistant materials, rigorously tested for over 600 days, were employed. These materials, combined with structural reinforcement and sealing of the pressure relief valve, mitigated the corrosion concerns and ensured a service life exceeding 15 years.

Industry Debate: Terminal and Pressure Relief Valve Placement

Despite the successful implementation of cell inversion in the Xiaomi SU7, there’s ongoing debate within the battery industry regarding the optimal placement of the terminal and pressure relief valve in inverted cell configurations. While the Kirin battery places both on the same side, competitors like SVOLT, with their Dragon Scale Armor battery, argue for separating them on opposite sides of the cell. Proponents of the latter approach cite simplified battery pack design and cost benefits as key advantages. This ongoing discussion highlights the continuous evolution of cell inversion technology as manufacturers strive to optimize battery pack design for safety, efficiency, and cost-effectiveness.

- Mitigation of Thermal Runaway Risks: By positioning the terminal and pressure relief valve on opposite sides of the battery cell, SVOLT aims to prevent potential interference between them during a thermal runaway event. In such a scenario, the gas and liquid released from the pressure relief valve could come into contact with the terminal if they were located on the same side. This contact might lead to short circuits or other electrical complications, exacerbating the situation. Separating them minimizes this risk.

- Simplified Battery Pack Design: Placing the terminal and pressure relief valve on opposing sides can simplify the overall design of the battery pack. Routing electrical connections and designing the pressure relief pathways becomes more straightforward when these components are not clustered together.

- Cost Optimization: The simplified design facilitated by separating the terminal and pressure relief valve can also contribute to cost reduction in battery pack manufacturing. Fewer specialized components and simpler assembly processes can translate to lower production costs.

Cell inversion represents a significant step forward in EV battery technology. Its ability to boost space utilization and enhance safety has made it a compelling design choice for manufacturers like Xiaomi. The implementation of this technology in the SU7, coupled with innovative solutions to address the inherent challenges, paves the way for wider adoption in future EVs. As research and development continue, cell inversion is poised to play a pivotal role in shaping the future of electric mobility.