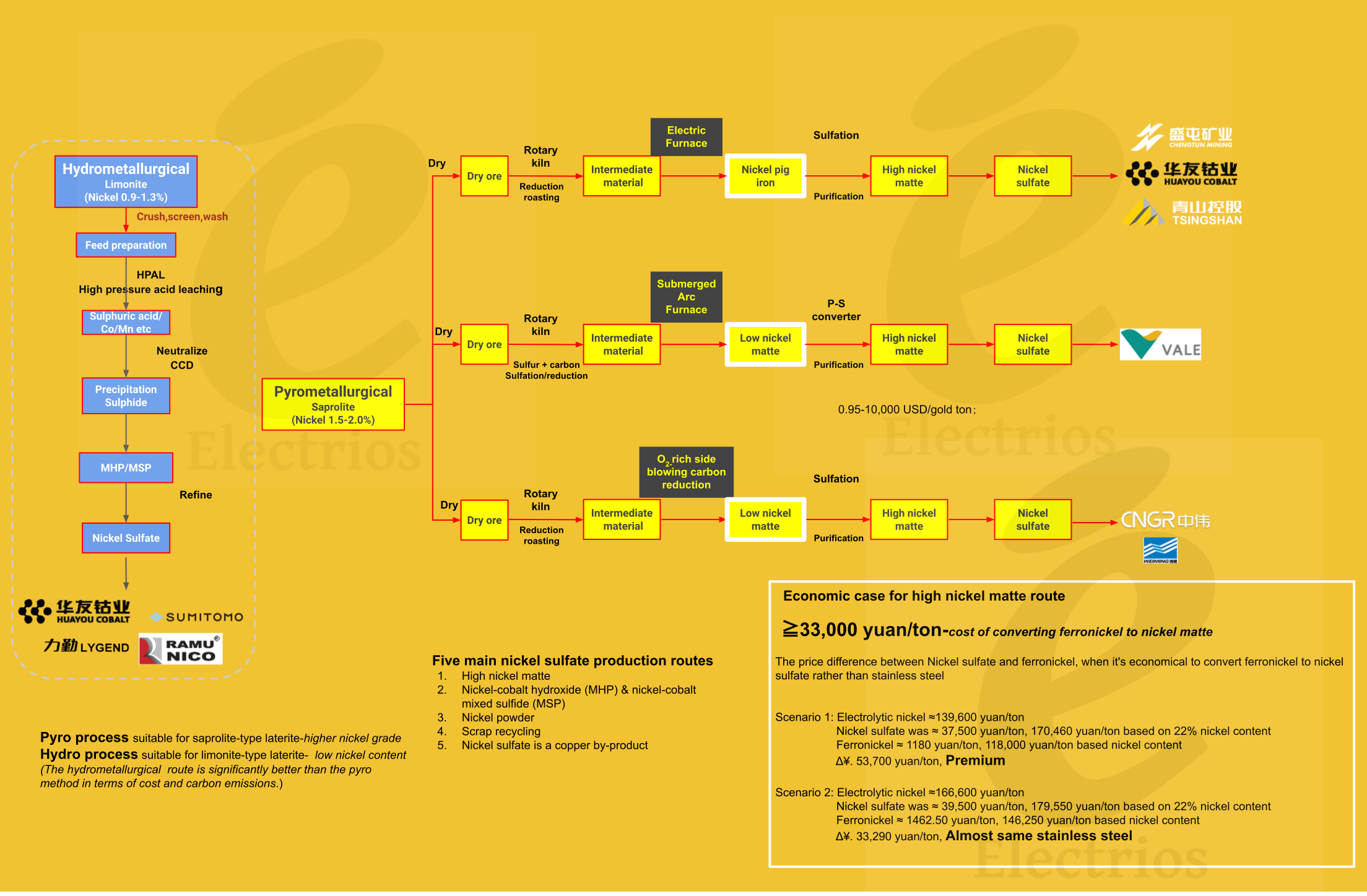

Laterite nickel to battery-grade nickel sulfate

Pyro process suitable for saprolite-type laterite-higher nickel grade

Hydro process suitable for limonite-type laterite- low nickel content

(The hydrometallurgical route is significantly better than the pyro method in terms of cost and carbon emissions.)

Five main nickel sulfate production routes

- High nickel matte

- Nickel-cobalt hydroxide (MHP) & nickel-cobalt mixed sulfide (MSP)

- Nickel powder

- Scrap recycling

- Nickel sulfate is a copper by-product

Economic case for high nickel matte route

≧33,000 yuan/ton-cost of converting ferronickel to nickel matte

The price difference between Nickel sulfate and ferronickel, when it’s economical to convert ferronickel to nickel sulfate rather than stainless steel

Scenario 1: Electrolytic nickel ≈139,600 yuan/ton

Nickel sulfate was ≈ 37,500 yuan/ton, 170,460 yuan/ton based on 22% nickel content

Ferronickel ≈ 1180 yuan/ton, 118,000 yuan/ton based nickel content

Δ¥. 53,700 yuan/ton, Premium

Scenario 2: Electrolytic nickel ≈166,600 yuan/ton

Nickel sulfate was ≈ 39,500 yuan/ton, 179,550 yuan/ton based on 22% nickel content

Ferronickel ≈ 1462.50 yuan/ton, 146,250 yuan/ton based nickel content

Δ¥. 33,290 yuan/ton, Almost same stainless steel